A staple gun, also known as a tacker or nailer, is a handheld tool used to drive heavy-duty staples into various materials, such as wood, plastic, or upholstery. It is a versatile tool that finds applications in numerous industries, from construction and woodworking to packaging and upholstery.

At its core, a staple gun consists of a few basic components: a housing that holds the staples, a firing mechanism (usually a lever or trigger), and a striking surface or nose that guides the staple into the material. When the firing mechanism is engaged, it releases a striking force that drives the staple out of the housing and into the target material.

Staple guns can be broadly categorized into two main types: manual and pneumatic (air-powered). Manual staple guns rely on the user’s physical effort to drive the staples, while pneumatic staple guns use compressed air to provide the striking force, making them more powerful and efficient for heavy-duty applications.

Within these two categories, staple guns can further be classified based on their size, staple capacity, and intended use. Some common types include:

- Hand-held Staple Guns: These are lightweight and portable, making them ideal for small projects and household tasks.

- Heavy-duty Staple Guns: Designed for industrial and construction applications, these guns can drive longer and thicker staples into tougher materials like hardwood or concrete.

- Upholstery Staple Guns: Specifically designed for upholstery work, these guns have a narrow nose and can shoot staples at an angle, allowing for precision placement in tight spaces.

- Flooring Staple Guns: Used for installing hardwood flooring, these guns can drive staples through the tongue-and-groove joints, securing the planks in place.

- Fencing Staple Guns: Designed for installing wire fencing or netting, these guns can drive staples through tough materials like metal posts or rails.

Regardless of the type, staple guns offer a convenient and efficient way to securely fasten materials together, making them an essential tool in various industries and DIY projects.

Table of Contents

History of Staple Guns

The origins of the staple gun can be traced back to the late 19th century when various inventors began experimenting with devices that could drive staples into materials more efficiently than manual hammering. One of the earliest patented designs was by George F. Mallory in 1877, which featured a hand-operated lever mechanism to drive staples into surfaces.

Over the next few decades, several improvements were made to the staple gun design, including the introduction of magazine-fed models that could hold multiple staples at once. In 1914, the Bostitch company (originally the Boston Wire Stitcher Company) introduced the first commercially successful staple gun, which quickly gained popularity in the construction and upholstery industries.

During World War II, the demand for staple guns surged as they became an essential tool for quickly and securely assembling wooden crates, boxes, and other packaging materials for military supplies. This period saw significant advancements in staple gun technology, with the introduction of pneumatic models that used compressed air to drive staples with greater force and efficiency.

In the post-war era, staple guns continued to evolve, with the introduction of electric and battery-powered models that offered even greater convenience and power. Today’s staple guns come in a wide range of sizes and designs, from lightweight handheld models for household use to heavy-duty industrial tools capable of driving staples into concrete and other dense materials.

Key milestones in the development of staple guns include the introduction of the first magazine-fed model in the early 20th century, the widespread adoption of pneumatic and electric models in the mid-20th century, and the integration of advanced features such as depth adjustment, safety mechanisms, and ergonomic designs in modern staple guns.

Common Uses of Staple Guns

Staple guns are versatile tools used in a wide range of applications, from upholstery and construction to packaging and bookbinding. Their ability to quickly and securely fasten materials together makes them indispensable in many industries and DIY projects.

Upholstery: Upholstery professionals rely heavily on staple guns to attach fabric, foam, and other materials to furniture frames. The powerful staples can penetrate through multiple layers, ensuring a tight and secure fit. Staple guns are essential tools for upholstering chairs, sofas, headboards, and other upholstered items.

Construction: In the construction industry, staple guns are used for various tasks, such as securing insulation, attaching house wrap or vapor barriers, and fastening construction netting or fencing. They are particularly useful for quickly attaching materials to wooden frames or studs, making them invaluable tools for framing, roofing, and siding projects.

Packaging: Staple guns play a crucial role in the packaging industry, where they are used to assemble and secure cardboard boxes, crates, and other shipping containers. Their ability to quickly and efficiently fasten materials together ensures that packages remain intact during transportation and handling.

Bookbinding: In the world of bookbinding, staple guns are used to bind the pages of books, notebooks, and other printed materials together. They provide a secure and efficient way to fasten the pages, creating a sturdy binding that can withstand regular use.

Crafts and DIY Projects: Staple guns are popular tools among crafters and DIY enthusiasts for their versatility and ease of use. They can be used for a wide range of projects, such as upholstering furniture, creating wall hangings, assembling picture frames, or attaching fabric to canvas for various craft projects.

With their ability to quickly and securely fasten materials together, staple guns have become essential tools in many industries and for various DIY projects. Whether you’re an upholsterer, a construction worker, a packaging professional, a bookbinder, or a crafter, a staple gun can be a valuable addition to your toolkit.

Types of Staple Guns

Staple guns come in three main types: manual, electric, and pneumatic. Each type has its own advantages and disadvantages, making it suitable for different applications.

Manual Staple Guns

Manual staple guns are the most basic and affordable option. They rely on the user’s physical strength to drive the staples into the material. These guns are typically lightweight and portable, making them ideal for small projects and occasional use. However, they can be tiring to use for extended periods or on tough materials.

Advantages:

- Inexpensive

- Lightweight and portable

- No power source required

- Simple to operate

Disadvantages:

- Require physical effort

- Limited driving power

- Slower than powered options

- Not suitable for heavy-duty tasks

Electric Staple Guns

Electric staple guns are powered by an electric motor, which provides the driving force to insert staples. These guns are more powerful than manual options and require less physical effort from the user. They are suitable for medium-duty tasks and can handle a variety of materials.

Advantages:

- More powerful than manual guns

- Less physical effort required

- Faster than manual guns

- Suitable for extended use

Disadvantages:

- Require a power source (battery or cord)

- More expensive than manual guns

- Heavier and less portable

Pneumatic Staple Guns

Pneumatic staple guns are the most powerful and heavy-duty option. They are powered by compressed air, which provides the driving force to insert staples into even the toughest materials. These guns are commonly used in construction, upholstery, and industrial applications.

Advantages:

- Extremely powerful

- Suitable for heavy-duty tasks

- Can handle a wide range of materials

- Fast and efficient

Disadvantages:

- Require an air compressor

- More expensive than manual and electric guns

- Heavier and less portable

- Require proper safety precautions

When choosing a staple gun, consider the intended use, the materials you’ll be working with, and your budget. Manual guns are suitable for light-duty tasks and occasional use, while electric and pneumatic guns are better suited for more demanding applications and frequent use.

Choosing the Right Staple Gun

Selecting the appropriate staple gun for your needs is crucial to ensure efficient and successful project completion. Several factors should be taken into consideration when choosing a staple gun.

Power Source: Staple guns are available in different power sources, including manual, electric, and pneumatic. Manual staple guns rely on hand pressure to drive the staples, making them suitable for light-duty tasks. Electric staple guns are powered by batteries or a cord, offering more driving force and convenience. Pneumatic staple guns, powered by compressed air, are the most powerful option, ideal for heavy-duty applications like framing and construction.

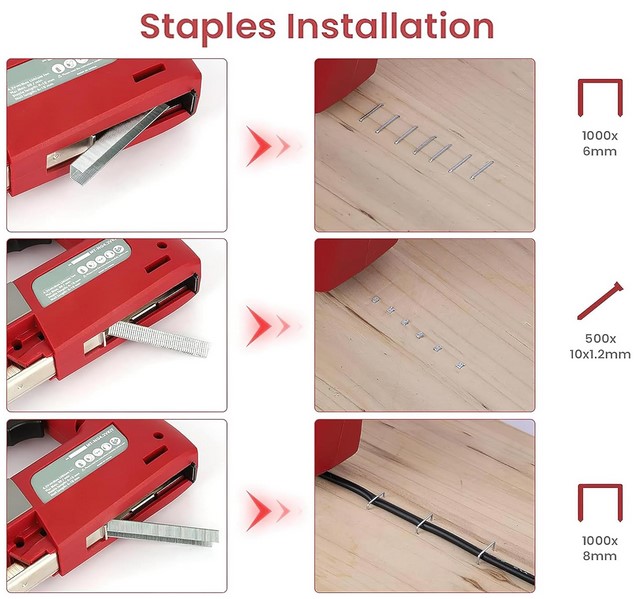

Staple Size: Staple guns accommodate various staple sizes, ranging from thin wire for upholstery to thick, heavy-duty staples for construction projects. Ensure that the staple gun you choose is compatible with the staple size required for your intended use.

Intended Use: Consider the type of project you’ll be working on. Light-duty staple guns are suitable for tasks like crafting, upholstery, and securing insulation or housewrap. Heavy-duty staple guns are necessary for framing, roofing, and other construction-related applications that require driving staples into dense materials like wood or concrete.

Ergonomics and Comfort: Look for a staple gun that fits comfortably in your hand and has a well-designed grip. This will help reduce fatigue and improve control during extended use.

Jam-Clearing Mechanism: Choose a staple gun with an easy-to-use jam-clearing mechanism, as jams are common and can be frustrating to deal with. Some models feature a quick-release mechanism or a clear view of the staple channel for easy jam removal.

Additional Features: Consider additional features that may be beneficial for your specific needs, such as adjustable depth control, a safety switch, and a staple viewer window to monitor staple supply.

By carefully evaluating these factors, you can select a staple gun that meets your project requirements, ensures safety, and provides a smooth and efficient working experience.

Staple Gun Safety

Staple guns are handy tools, but they can also be dangerous if not handled properly. Proper handling, protective equipment, and safety precautions are essential when using staple guns to prevent accidents and injuries.

First and foremost, always treat a staple gun as you would treat any other power tool or firearm. Never point the staple gun at yourself or others, even if you think it’s unloaded or not connected to an air compressor. Keep your finger off the trigger until you’re ready to fire, and ensure the safety mechanism is engaged when not in use.

When operating a staple gun, wear appropriate personal protective equipment (PPE) such as safety glasses or goggles to protect your eyes from flying debris or ricocheting staples. Gloves can also help prevent injuries to your hands, especially when working with heavy-duty staple guns or in tight spaces.

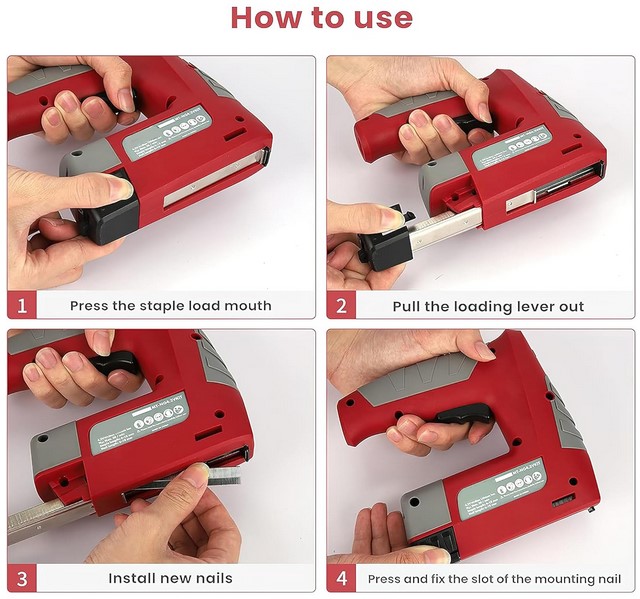

Before using a staple gun, inspect it for any damage or wear and tear. Check the safety mechanisms, trigger, and nose piece for proper functioning. Ensure that the staple gun is compatible with the type and size of staples you plan to use, and always follow the manufacturer’s instructions for loading and operating the tool.

Be aware of your surroundings and ensure that the area behind and around your work surface is clear of any obstructions or people. Staple guns can fire staples with enough force to penetrate surfaces or cause serious injury if they ricochet or miss their intended target.

When not in use, always disconnect the staple gun from its power source, whether it’s an air compressor or battery pack. Store the tool in a secure location, out of reach of children or unauthorized individuals.

In case of a staple gun misfire or jam, never attempt to clear it by force or with your fingers. Follow the manufacturer’s instructions for safely clearing jams, and if necessary, seek assistance from a professional or contact the manufacturer for guidance.

By following these safety precautions and handling staple guns with care, you can minimize the risk of accidents and injuries, ensuring a safe and productive work environment.

Staple Gun Maintenance

Proper maintenance is crucial to ensure your staple gun operates smoothly and lasts for years. Regular cleaning, lubrication, and troubleshooting can prevent jams, misfires, and premature wear.

Cleaning:

Before cleaning, always ensure the staple gun is unloaded and disconnected from any power source. Use a soft-bristle brush or compressed air to remove debris from the magazine, nose, and firing mechanism. Wipe down the exterior with a clean, dry cloth.

Lubrication:

Lubrication is essential for smooth operation and preventing rust. Apply a few drops of lightweight machine oil or lubricant to the moving parts, such as the plunger and pivot points. Avoid over-lubricating, as excess oil can attract dust and grime.

Troubleshooting Common Issues:

- Jams: If staples become jammed, do not force the gun. Carefully remove the jammed staple(s) using pliers or a staple remover tool. Inspect the magazine and firing mechanism for any obstructions or damage.

- Misfires: If the staple gun fails to fire or drives staples incompletely, check for proper staple size and compatibility. Ensure the magazine is loaded correctly and the firing mechanism is not obstructed.

- Leaks: If air or oil leaks are present, inspect for worn or damaged seals and gaskets. Replace any faulty components.

- Stuck Staples: If staples become stuck in the nose, use a soft punch or dowel to gently tap them out. Avoid using sharp objects that could damage the gun.

Regular maintenance and prompt troubleshooting can significantly extend the lifespan of your staple gun and ensure optimal performance for all your stapling needs.

Staple Gun Accessories

Staple guns are versatile tools, but their functionality can be further expanded with the right accessories. From different staple types and sizes to specialized attachments, these add-ons allow you to tackle a broader range of projects and materials.

Staple Assortments: Manufacturers offer staple assortments in various lengths and gauges to accommodate different materials and applications. Shorter staples are ideal for delicate tasks like upholstery, while longer ones provide a stronger grip for heavy-duty projects like framing or roofing.

Brad Nailers: These specialized nailers shoot thin, headless brads instead of staples, making them perfect for delicate woodworking tasks like trim work, cabinetry, and furniture assembly. Brad nailers offer a more discreet finish than staples.

Narrow Crown Staplers: Designed for tight spaces and intricate work, narrow crown staplers fire staples with a narrower crown width, allowing them to fit into tighter corners and crevices.

Long Nose Attachments: These attachments extend the reach of your staple gun, enabling you to access hard-to-reach areas or fire staples at an angle. They’re particularly useful for upholstery projects, where you need to staple fabric in tight spaces.

Insulation Stapler Attachments: These specialized attachments are designed to securely fasten insulation materials like fiberglass or foam to studs or joists, making insulation installation easier and more efficient.

Anti-Jam Mechanisms: Some staple guns feature anti-jam mechanisms that prevent staples from jamming inside the tool, reducing frustration and downtime during projects.

By investing in the right accessories, you can transform your staple gun into a versatile tool capable of handling a wide range of tasks with precision and efficiency.

Staple Gun Brands

A staple gun is a handy tool that can make various tasks easier and more efficient. In the market, several reputable brands offer high-quality staple guns to cater to different needs. Here’s an overview of some popular and reliable staple gun manufacturers:

Stanley: One of the most recognized names in the tool industry, Stanley has been producing durable and reliable staple guns for decades. Their products are known for their sturdy construction, ergonomic design, and ease of use.

Arrow Fastener: Arrow Fastener is a leading manufacturer of staple guns and other fastening tools. Their staple guns are designed for both professional and DIY applications, offering a wide range of models with various features and capabilities.

Bostitch: Bostitch is another well-known brand that specializes in fastening tools, including staple guns. Their products are renowned for their quality, performance, and versatility, making them a popular choice among professionals and homeowners alike.

Dewalt: As a subsidiary of Stanley Black & Decker, Dewalt is a trusted name in the power tool industry. Their staple guns are designed with a focus on durability, ergonomics, and efficient performance, making them a favorite among contractors and professionals.

Porter-Cable: Porter-Cable is a reputable brand that offers a variety of staple guns for various applications, from upholstery to framing. Their products are known for their reliability, ease of use, and affordability.

Senco: Senco is a leading manufacturer of professional-grade fastening tools, including a wide range of staple guns. Their products are designed for heavy-duty applications and are highly regarded for their durability and performance.

These are just a few examples of the many reputable staple gun brands available in the market. When choosing a staple gun, it’s essential to consider factors such as intended use, ergonomics, power source (manual or pneumatic), and overall quality to ensure you get the right tool for your needs.

Staple Gun Alternatives

While staple guns are versatile and widely used for various fastening tasks, there are several alternative methods and tools available depending on the project requirements and materials involved. Some of the popular alternatives to staple guns include:

Nails and Hammers: One of the most traditional and reliable fastening methods, nails and hammers are ideal for woodworking projects, framing, and construction tasks. Different types of nails, such as finishing nails, brad nails, or common nails, can be used based on the application.

Screws and Screwdrivers: Screws offer a more secure and permanent fastening solution compared to staples, especially for heavy-duty applications or when disassembly is required. Various types of screws, such as wood screws, drywall screws, or machine screws, can be driven using manual or power screwdrivers.

Adhesives and Glues: For certain materials like fabrics, plastics, or delicate surfaces, adhesives and glues can provide a cleaner and more secure bond without the need for physical fasteners. Different types of adhesives, including hot glue guns, epoxy, or construction adhesives, can be used based on the project requirements.

Rivets and Rivet Guns: Rivets are permanent fasteners that are ideal for joining metal components or materials that cannot be penetrated by nails or screws. Rivet guns are specialized tools used to install rivets, providing a strong and durable connection.

Welding and Soldering: In metalworking and certain industrial applications, welding and soldering techniques can be used to permanently join metal components together. These methods require specialized equipment and skills but offer exceptional strength and durability.

Zippers and Velcro: For textile and fabric applications, zippers and Velcro (hook-and-loop fasteners) can be used as alternatives to staples for joining or closing materials.

The choice of fastening method depends on factors such as the materials being joined, the desired strength and permanence of the connection, the project requirements, and personal preferences. It’s important to evaluate the pros and cons of each alternative and select the most suitable option for the task at hand.

Staple Gun Tips and Tricks

A staple gun is a versatile tool that can make many tasks easier, but only if you know how to use it effectively. Here are some tips and tricks to help you get the most out of your staple gun:

Prepare the Surface: Before firing staples, ensure the surface is clean and free of debris. Any dirt or obstacles can cause the staples to jam or misfire, leading to frustration and potential damage.

Adjust the Depth: Most staple guns allow you to adjust the depth at which the staples are driven into the material. Experiment with different depth settings to find the right balance between secure fastening and avoiding damage to the surface.

Use a Backstop: When stapling into thin or delicate materials, place a piece of scrap wood or a thick book behind the area you’re stapling. This backstop will prevent the staples from punching through and damaging the surface underneath.

Stagger Staples: For added strength and stability, stagger the placement of your staples instead of firing them in a straight line. This technique helps distribute the tension and prevents the material from tearing along the line of staples.

Lubricate the Mechanism: Keep your staple gun well-lubricated to ensure smooth operation and prevent jams. A few drops of machine oil or a silicone-based lubricant can work wonders in maintaining the tool’s performance.

Use the Right Staples: Different staple guns are designed for specific staple sizes and materials. Using the wrong staples can lead to jams, misfires, and potentially damage the tool or the surface you’re working on. Always consult the manufacturer’s recommendations.

Secure the Material: When working with larger or unwieldy materials, secure them in place before stapling. This will prevent the material from shifting or moving during the stapling process, ensuring accurate and consistent staple placement.

Clear Jams Safely: If your staple gun becomes jammed, never attempt to force the staples through or disassemble the tool without proper guidance. Consult the manufacturer’s instructions or seek professional assistance to avoid potential injury or further damage to the tool.

By following these tips and tricks, you’ll be able to use your staple gun more efficiently, achieve better results, and extend the life of your tool.

Staple Gun in DIY and Crafts

Staple guns have become a versatile tool in the world of DIY projects and crafts, allowing for creative and innovative applications beyond their traditional use. Crafters and DIY enthusiasts have discovered unique ways to incorporate staple guns into their projects, adding texture, dimension, and artistic flair.

One popular application is using staple guns to create unique wall art or decorative pieces. By strategically arranging staples on a canvas or wooden board, artists can create intricate patterns, geometric designs, or even portraits. The raised texture of the staples adds depth and visual interest, transforming ordinary materials into captivating works of art.

Staple guns can also be used in upholstery projects, such as reupholstering furniture or creating custom cushions and pillows. The staples securely hold the fabric in place, allowing for a professional-looking finish. Additionally, crafters have found creative ways to incorporate staples into fabric projects, such as quilting or embroidery, adding unique textures and embellishments.

In the realm of home decor, staple guns can be used to create stunning wall hangings or room dividers by weaving materials like yarn, ribbons, or even recycled materials through a grid of staples. This technique not only adds a decorative element but also allows for customization and personalization.

Staple guns can also be used in book-binding projects, helping to securely hold the pages together while adding a unique touch. Crafters can experiment with different materials, such as leather or fabric, to create personalized journals or sketchbooks.

Furthermore, staple guns have found their way into jewelry-making, where they can be used to attach various materials like leather, felt, or even metal to create unique and eye-catching pieces. The versatility of staple guns allows for endless creativity and experimentation in this realm.

Overall, the staple gun has proven to be a versatile tool in the world of DIY and crafts, enabling artists and crafters to explore new techniques, textures, and creative expressions. With a little imagination and innovation, the humble staple gun can be transformed into a powerful tool for artistic expression and personalized projects.

Environmental Impact of Staple Guns

Staple guns, like many tools and devices, have an environmental impact that should be considered. The production, use, and disposal of staple guns and their staples can contribute to various environmental issues, such as resource depletion, energy consumption, and waste generation.

Sustainability Considerations:

- Manufacturing Process: The manufacturing of staple guns and staples involves the extraction and processing of raw materials like steel, plastics, and other components. These processes can be energy-intensive and contribute to greenhouse gas emissions, water pollution, and habitat destruction.

- Energy Consumption: The operation of staple guns, especially electric or pneumatic models, requires energy consumption. While the energy usage per individual use may be relatively low, the cumulative impact of widespread staple gun usage can be significant.

- Waste Generation: Staple guns and their staples eventually become waste products, contributing to the growing problem of solid waste management. Improper disposal of these items can lead to environmental pollution and harm to wildlife.

Recycling and Eco-friendly Alternatives:

- Recycling: Many staple gun components, particularly the metal parts, can be recycled. Proper recycling of staple guns and staples can help reduce the demand for new raw materials and minimize waste.

- Eco-friendly Staples: Some manufacturers offer eco-friendly staples made from recycled or biodegradable materials, such as paper or plant-based plastics. These alternatives can help reduce the environmental impact associated with traditional metal staples.

- Reusable Fasteners: In some applications, reusable fasteners like clips or clamps can be used as an alternative to staples. These options can reduce waste and the need for frequent replacement.

- Energy-efficient Models: Choosing energy-efficient staple gun models, particularly for electric or pneumatic types, can help reduce energy consumption and associated emissions.

- Proper Maintenance and Repair: Proper maintenance and repair of staple guns can extend their lifespan, reducing the need for frequent replacements and minimizing waste.

By considering these sustainability considerations and eco-friendly alternatives, individuals and businesses can contribute to reducing the environmental impact of staple gun usage and promote more sustainable practices.

Future of Staple Guns

Staple guns have come a long way since their inception, and the future holds exciting possibilities for further advancements in this versatile tool. As technology continues to evolve, we can expect to see innovations that enhance the efficiency, precision, and user-friendliness of staple guns.

One area of potential development is the integration of smart technology. Imagine a staple gun that can automatically adjust its depth and force settings based on the material being stapled, ensuring optimal penetration and minimizing the risk of jamming or misfiring. Additionally, these smart staple guns could be equipped with sensors that detect potential obstructions or misalignments, preventing accidental injuries or damage.

Another exciting prospect is the incorporation of advanced ergonomic designs. Manufacturers may explore the use of lightweight yet durable materials, as well as contoured grips and adjustable handles, to reduce user fatigue and increase comfort during extended use. Vibration-dampening technologies could also be implemented to minimize hand and arm strain.

The future may also bring advancements in power sources for staple guns. While traditional pneumatic and electric models will likely remain popular, we may see the emergence of more efficient and eco-friendly options, such as rechargeable lithium-ion batteries or even solar-powered variants for outdoor applications.

In terms of functionality, we could witness the development of staple guns capable of handling a wider range of materials and thicknesses, from delicate fabrics to heavy-duty construction materials. Additionally, manufacturers may explore the possibility of interchangeable nozzles or heads, allowing users to switch between different staple types or configurations for various applications.

Furthermore, the integration of digital interfaces and connectivity features could revolutionize the way we use staple guns. Imagine being able to wirelessly program your staple gun with specific settings or patterns, or even remotely monitor its performance and maintenance needs through a mobile app or cloud-based platform.

As the demand for sustainable and environmentally conscious practices grows, we may also see the development of staple guns that prioritize eco-friendly materials and manufacturing processes. This could include the use of recycled or biodegradable plastics, as well as the implementation of energy-efficient technologies and reduced waste generation.

The future of staple guns is exciting and full of possibilities. With the continuous advancements in technology and a focus on user experience, efficiency, and sustainability, these humble tools are poised to become even more versatile, precise, and indispensable in a wide range of applications.