A ladder foothold, also known as a ladder foot or ladder base, is an essential accessory designed to provide stability and secure footing for ladders. These devices are typically made of durable materials like rubber, plastic, or metal, and are attached to the bottom of a ladder’s legs.

Ladder footholds serve several crucial purposes:

- Increased Safety: By providing a firm grip on various surfaces, ladder footholds help prevent slips, slides, and potential accidents. This added stability is particularly important when working on uneven or slippery surfaces, such as roofs, stairs, or wet floors.

- Surface Protection: Many ladder footholds feature non-marking or non-slip pads that protect the surface underneath from scratches, dents, or damage. This feature is especially valuable when working on delicate floors or surfaces that can easily be marred.

- Versatility: Ladder footholds come in various designs to accommodate different surface types, including flat surfaces, stairs, and uneven terrain. This versatility allows ladders to be used safely in a wide range of environments, from construction sites to residential settings.

- Longevity: By distributing the weight of the ladder and user more evenly, ladder footholds help reduce wear and tear on the ladder’s legs, prolonging the ladder’s lifespan and ensuring long-term durability.

Ladder footholds are widely used in various industries, including construction, maintenance, painting, window cleaning, and residential applications. They are an essential safety component for anyone working at heights or using ladders, as they help prevent accidents and injuries caused by ladder instability or slips.

Table of Contents

Types of Ladder Footholds

Ladder footholds come in various materials, designs, and styles to suit different applications and surface conditions. The most common types include:

Rubber Footholds: These are made of durable rubber compounds and offer excellent traction on smooth surfaces like concrete, tile, or hardwood floors. Rubber footholds are available in different shapes, such as flat pads, spiked grips, or circular bases.

Spiked Footholds: Designed for use on softer surfaces like soil, grass, or gravel, spiked footholds have sharp metal or plastic spikes that dig into the ground for enhanced stability. They are commonly used in outdoor applications like construction sites or landscaping.

Adjustable Footholds: These versatile footholds feature adjustable components that allow them to adapt to different surface angles and contours. They often have swiveling or pivoting mechanisms that ensure the foothold remains level and secure, even on uneven terrain.

Magnetic Footholds: Ideal for use on metal surfaces, magnetic footholds rely on powerful magnets to create a strong grip. They are commonly used by steel workers, roofers, or anyone working on metal structures or roofs.

Anti-Slip Footholds: These footholds are designed with specialized coatings or textures that provide exceptional traction on wet or slippery surfaces. They are often made of materials like aluminum oxide or silicon carbide for enhanced grip.

Leveling Footholds: These footholds incorporate built-in leveling mechanisms, such as adjustable legs or swiveling bases, to ensure the ladder remains level and stable on uneven surfaces. They are particularly useful in construction and industrial settings.

Regardless of the type, ladder footholds are designed to provide a secure and stable base for ladders, ensuring user safety and preventing accidents caused by slips or falls.

Safety Considerations

Proper installation, maintenance, and use of ladder footholds are crucial for ensuring safety when working at heights. Ladder footholds play a vital role in providing stability and preventing accidents, such as slips, falls, and injuries.

Importance of Proper Installation:

- Follow manufacturer’s instructions carefully for correct installation.

- Ensure the ladder foothold is securely attached to the ladder and the surface it is resting on.

- Check that the foothold is level and stable, preventing any rocking or wobbling.

- Use appropriate fasteners and anchors suitable for the surface and weight load.

Maintenance and Inspection:

- Regularly inspect ladder footholds for signs of wear, damage, or corrosion.

- Replace any worn or damaged components immediately.

- Clean footholds to remove dirt, debris, or buildup that could affect grip or stability.

- Lubricate moving parts as per manufacturer’s recommendations.

Proper Use:

- Always ensure the ladder foothold is correctly positioned and secured before climbing.

- Distribute weight evenly on the ladder, avoiding excessive leaning or reaching.

- Use caution when working on uneven or slippery surfaces.

- Never exceed the maximum weight capacity of the ladder or foothold.

- Wear appropriate non-slip footwear for added traction and safety.

By prioritizing the proper installation, maintenance, and use of ladder footholds, workers can significantly reduce the risk of accidents and injuries while working at heights. Adhering to safety guidelines and following best practices is crucial for maintaining a safe work environment.

Applications in Construction and Maintenance

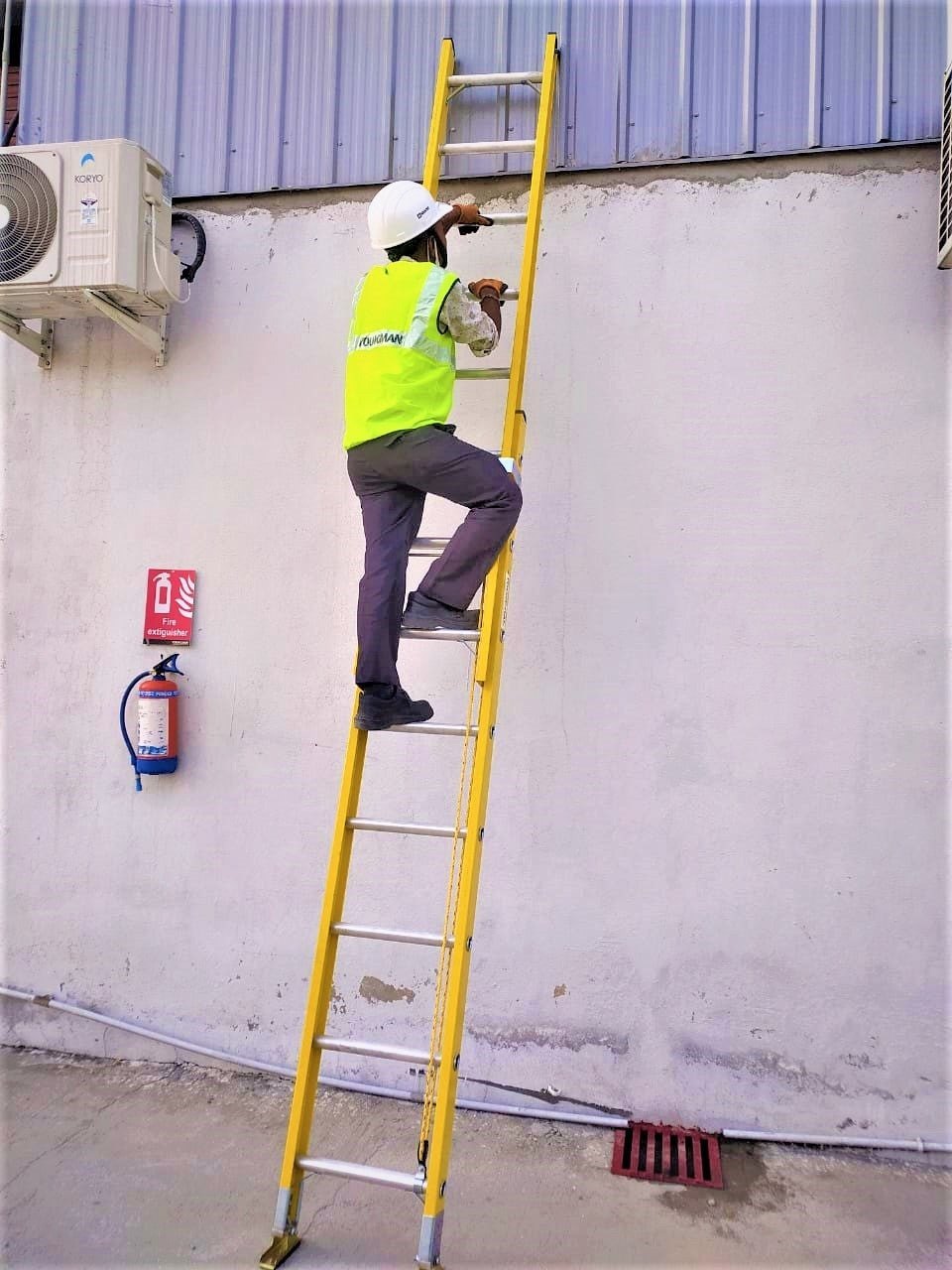

Ladder footholds are essential tools in the construction and maintenance industries, providing a secure and stable base for ladders used in various tasks. In construction, ladder footholds are employed during the erection of buildings, bridges, and other structures, allowing workers to safely access elevated areas.

During the framing and roofing stages, ladder footholds enable carpenters and roofers to securely position their ladders on uneven or sloped surfaces, reducing the risk of accidents caused by ladder slippage. Similarly, in the finishing stages, painters, electricians, and plumbers rely on ladder footholds to maintain stable ladder positioning while working at heights.

In the maintenance sector, ladder footholds are indispensable for tasks such as window cleaning, gutter cleaning, and exterior building repairs. By providing a firm grip on various surfaces, ladder footholds allow maintenance workers to safely access hard-to-reach areas without compromising their stability or safety.

Additionally, ladder footholds are widely used in industrial settings, such as manufacturing plants, warehouses, and power plants, where maintenance and repair work often requires accessing elevated machinery or equipment. The rugged and durable construction of ladder footholds ensures they can withstand the demanding conditions of these environments, providing a reliable solution for worker safety.

Residential and DIY Uses

Ladder footholds are invaluable tools for homeowners and DIY enthusiasts tackling various projects around the house. From painting and cleaning to minor repairs and home improvements, these versatile devices provide a stable and secure base for ladders, ensuring safety and efficiency.

One of the most common residential applications for ladder footholds is interior and exterior painting. Whether you’re refreshing the walls of a living room or giving your home’s exterior a new coat of paint, ladder footholds allow you to securely position your ladder on uneven surfaces, such as lawns, decks, or patios. This not only prevents the ladder from sinking into soft ground or sliding on hard surfaces but also provides a level and stable platform for comfortable and safe painting.

Ladder footholds are also essential for tasks that require working at heights, such as cleaning gutters, trimming trees, or installing holiday lights. By providing a secure foothold, these devices eliminate the risk of ladder slippage, which can lead to dangerous falls and injuries. Additionally, they allow you to work with both hands free, increasing productivity and efficiency.

Home improvement projects, such as roof repairs, window replacements, or installing siding, often require the use of ladders on various surfaces. Ladder footholds ensure that your ladder remains steady and secure, even on uneven or sloped terrain, preventing potential accidents and enabling you to focus on the task at hand.

For DIY enthusiasts, ladder footholds are indispensable when working on projects like building decks, sheds, or outdoor structures. These devices provide a stable base for your ladder, allowing you to work confidently and safely, even on uneven or soft ground.

Overall, ladder footholds are essential tools for residential and DIY applications, offering homeowners and DIY enthusiasts a safe and secure way to work at heights, tackle home improvement projects, and complete tasks efficiently and confidently.

Installation and Maintenance

Proper installation and regular maintenance are crucial for ensuring the safety and longevity of ladder footholds. Follow these best practices for optimal performance:

Installation Techniques:

- Prepare the surface: Clean the area where the foothold will be installed, ensuring it’s free from debris, dirt, and any loose materials that could compromise adhesion.

- Mark the position: Carefully measure and mark the desired location for the foothold, ensuring it aligns with the ladder’s rungs or steps.

- Apply adhesive (if required): Some footholds require the use of a specialized adhesive for secure bonding. Follow the manufacturer’s instructions for proper application and curing times.

- Secure the foothold: Firmly press the foothold onto the marked surface, ensuring even contact and proper alignment. For mechanical fasteners, follow the specific installation instructions provided.

- Allow curing time: If using adhesives, allow the recommended curing time before applying any weight or stress to the foothold.

Maintenance Tips:

- Regular inspections: Periodically inspect the footholds for any signs of wear, damage, or loosening. Check for cracks, deformation, or separation from the surface.

- Clean the surface: Keep the footholds and surrounding areas clean to prevent the buildup of dirt, grease, or other contaminants that could affect traction or adhesion.

- Replace when necessary: If a foothold shows significant wear or damage, replace it promptly to maintain safety and prevent potential accidents.

- Follow manufacturer guidelines: Consult the manufacturer’s recommendations for specific maintenance procedures, replacement intervals, and compatible cleaning products.

- Protect from environmental factors: In outdoor applications, consider protecting the footholds from excessive sun exposure, moisture, or extreme temperatures, as these factors can accelerate deterioration.

By following proper installation techniques and adhering to regular maintenance practices, ladder footholds can provide reliable traction and support, ensuring a safer working environment for users.

Regulations and Standards

Ladder footholds are subject to various industry regulations and safety standards to ensure the protection of workers and users. These guidelines are established by organizations such as the Occupational Safety and Health Administration (OSHA), the American National Standards Institute (ANSI), and the Canadian Standards Association (CSA).

OSHA has set forth specific requirements for the use of ladders in the workplace, including guidelines for ladder footholds. These regulations cover aspects such as the maximum height allowed for ladder use, load-bearing capacities, and the proper installation and maintenance of ladder footholds. Employers are responsible for providing ladders and footholds that comply with OSHA standards and ensuring that workers are trained in their safe use.

ANSI and CSA have developed comprehensive standards for the design, testing, and performance of ladder footholds. These standards specify requirements for materials, construction, load capacities, and labeling. Manufacturers must ensure that their ladder footholds meet these standards before they can be sold and used in various industries.

In addition to these overarching regulations, specific industries may have their own guidelines and best practices for the use of ladder footholds. For example, the construction industry may have additional requirements for the use of footholds on scaffolding or in confined spaces, while the utility industry may have specific protocols for using footholds when working on power lines or telecommunication towers.

Compliance with these regulations and standards is crucial for ensuring the safety of workers and users. Failure to adhere to these guidelines can result in fines, legal liabilities, and potentially serious accidents or injuries. It is essential for employers, contractors, and individuals to stay up-to-date with the latest regulations and standards, and to implement proper training and safety protocols when using ladder footholds.

Choosing the Right Ladder Foothold

Selecting the appropriate ladder foothold is crucial for ensuring safety and stability during various tasks and applications. Several factors should be considered when choosing the right ladder foothold:

Surface Type: The surface on which the ladder will be placed plays a significant role in determining the suitable foothold. Different footholds are designed for specific surfaces, such as concrete, wood, tile, or uneven terrain. Using the wrong foothold on an incompatible surface can lead to slipping or instability.

Load Capacity: Ladder footholds are rated for specific load capacities, which refer to the maximum weight they can safely support. It’s essential to choose a foothold that can accommodate the combined weight of the ladder, the person climbing it, and any equipment or materials being carried.

Adjustability: Some ladder footholds offer adjustability features, allowing them to adapt to uneven or sloping surfaces. Adjustable footholds can provide better stability and prevent the ladder from rocking or shifting during use.

Durability and Material: Ladder footholds are available in various materials, such as rubber, plastic, or metal. The material choice should be based on the intended use and environmental conditions. For example, rubber footholds may be preferred for outdoor use due to their slip-resistant properties, while metal footholds may be more suitable for heavy-duty applications.

Compatibility: Ensure that the ladder foothold is compatible with the type and size of the ladder being used. Some footholds are designed specifically for certain ladder styles, such as extension ladders, step ladders, or multi-purpose ladders.

Ease of Use: Consider the ease of installation and removal when choosing a ladder foothold. Some footholds feature quick-release mechanisms or tool-free adjustments, which can save time and effort during setup and breakdown.

Portability: If you need to transport the ladder and foothold frequently, portability and weight should be taken into account. Lightweight and compact footholds may be preferable for increased mobility and convenience.

By carefully considering these factors, you can select the most appropriate ladder foothold for your specific task or application, ensuring maximum safety, stability, and efficiency during use.

Accessories and Attachments

Ladder footholds can be enhanced with various accessories and attachments to improve safety, stability, and functionality. These additional components are designed to cater to specific job requirements or environmental conditions, ensuring a secure and efficient work experience.

One popular accessory is the ladder leveler, which helps compensate for uneven or sloping surfaces. These levelers attach to the foothold and provide adjustable legs or pads, allowing the ladder to be stabilized on uneven terrain. This accessory is particularly useful in construction sites, roofing projects, or any situation where the ground is not perfectly level.

Another useful attachment is the ladder grip, which provides additional traction and grip on slippery or smooth surfaces. These grips are typically made of durable rubber or metal and can be easily attached to the foothold, preventing the ladder from sliding or shifting during use. They are ideal for use on tile floors, polished concrete, or any surface where extra grip is required.

For added safety, ladder foothold accessories like stabilizers or outriggers can be employed. These devices extend outward from the foothold, increasing the overall footprint and stability of the ladder. They are particularly beneficial when working at heights or in windy conditions, as they help prevent the ladder from tipping over.

In certain industrial or commercial settings, ladder footholds may need to be anchored or secured to the ground. In such cases, anchor systems or tie-down kits can be used in conjunction with the footholds. These attachments typically involve ground stakes, chains, or straps that secure the ladder to a fixed point, ensuring it remains stable during use.

For added convenience, some ladder footholds can accommodate tool trays or tool holders. These attachments allow workers to keep their tools and equipment within easy reach, reducing the need to climb up and down the ladder frequently. This not only saves time but also enhances safety by minimizing the risk of dropping tools from heights.

Manufacturers often offer customized or specialized accessories and attachments tailored to specific industries or applications. For example, footholds designed for use in electrically charged environments may include insulated components or grounding attachments to prevent electrical hazards.

Future Trends and Innovations

The ladder foothold industry is continuously evolving, driven by the demand for enhanced safety, durability, and user-friendly designs. Emerging technologies, innovative materials, and cutting-edge design concepts are shaping the future of ladder footholds.

One notable trend is the integration of advanced sensors and smart technologies into ladder footholds. These intelligent systems can detect potential hazards, monitor usage patterns, and provide real-time feedback to users, improving overall safety and efficiency. Additionally, the development of self-adjusting and self-leveling mechanisms is gaining traction, ensuring optimal stability on uneven surfaces.

Material innovation is also playing a crucial role in the evolution of ladder footholds. Lightweight yet incredibly strong composite materials, such as carbon fiber reinforced polymers, are being explored to create footholds that are both durable and easy to maneuver. Additionally, the incorporation of recycled and sustainable materials aligns with the growing emphasis on environmental responsibility.

Design innovations are focused on improving ergonomics and user experience. Adjustable and customizable ladder footholds are being developed to accommodate various user preferences and job site conditions. Furthermore, the integration of anti-slip and shock-absorbing features enhances traction and reduces the risk of accidents.

In the realm of manufacturing, advanced 3D printing and additive manufacturing techniques are enabling the production of highly customized and intricate ladder foothold designs. This not only allows for greater design flexibility but also streamlines the manufacturing process, reducing lead times and costs.

As the industry continues to evolve, we can expect to see even more innovative solutions that prioritize safety, efficiency, and user-friendliness, ensuring that ladder footholds remain an essential tool for professionals and DIY enthusiasts alike.

Frequently Asked Questions

What are ladder footholds used for?

Ladder footholds are safety devices designed to provide a secure and stable base for ladders. They help prevent ladders from slipping or sinking into soft ground, ensuring a firm footing and reducing the risk of accidents and injuries during climbing or descending.

Are ladder footholds necessary for all ladder types?

While ladder footholds are not strictly required for every ladder type or situation, they are highly recommended, especially when working on uneven, soft, or unstable surfaces. They provide an additional layer of safety and stability, which is crucial when working at heights or in precarious conditions.

How do I choose the right ladder foothold?

When selecting ladder footholds, consider the type of surface you’ll be working on (concrete, soil, gravel, etc.), the weight capacity required, and the size and shape of your ladder’s feet. Some footholds are adjustable to accommodate different ladder sizes, while others are designed for specific applications.

Can ladder footholds be used on sloped or uneven surfaces?

Yes, many ladder footholds are designed to be used on sloped or uneven surfaces. Some models feature adjustable legs or swiveling bases that allow the foothold to adapt to the terrain, ensuring a secure and level base for the ladder.

How do I properly install and maintain ladder footholds?

Follow the manufacturer’s instructions carefully when installing ladder footholds. Ensure they are securely attached to the ladder feet and adjusted to the appropriate height and angle. Regularly inspect the footholds for wear, damage, or looseness, and replace them if necessary.

Are there any special considerations for using ladder footholds in certain environments or industries?

Yes, certain industries or environments may have specific regulations or guidelines regarding the use of ladder footholds. For example, construction sites, industrial facilities, or outdoor work environments may have stricter safety protocols or require footholds that meet specific standards or certifications.