What is a 5 Gallon Oil Pump?

A 5 gallon oil pump is a compact and portable device designed to transfer various types of oils and lubricants from larger containers or reservoirs into smaller containers or machinery. It is commonly used in automotive, industrial, and commercial settings where the efficient and controlled transfer of oils is essential.

Definition: A 5 gallon oil pump is a self-priming, hand-operated pump that can efficiently transfer up to 5 gallons (approximately 19 liters) of oil or lubricant per cycle. It typically consists of a sturdy pump body, a suction tube or hose, a discharge nozzle or spout, and a handle or lever mechanism for manual operation.

Common Uses: These pumps are widely used for a variety of applications, including:

- Transferring engine oil, gear oil, hydraulic fluid, and other lubricants into vehicles, machinery, and equipment.

- Dispensing oil from bulk containers or drums into smaller containers for storage or transportation.

- Refilling oil reservoirs in industrial equipment, such as compressors, generators, and pumps.

- Lubricating machinery and equipment in workshops, garages, and manufacturing facilities.

Basic Components: A typical 5 gallon oil pump consists of the following main components:

- Pump Body: The pump body is the main housing that contains the pumping mechanism and provides a sturdy base for operation.

- Suction Tube or Hose: This flexible tube or hose is connected to the pump inlet and is inserted into the oil container or reservoir to draw in the oil.

- Discharge Nozzle or Spout: The discharge nozzle or spout is connected to the pump outlet and allows for precise and controlled dispensing of the oil into the desired container or machinery.

- Handle or Lever: The handle or lever is the manual mechanism used to operate the pump, creating the suction and discharge action for transferring the oil.

- Base or Mounting: Some pumps have a sturdy base or mounting system to ensure stability during operation and prevent tipping or spilling.

Table of Contents

Types of 5 Gallon Oil Pumps

5 gallon oil pumps are available in various types to cater to different needs and applications. The primary types include:

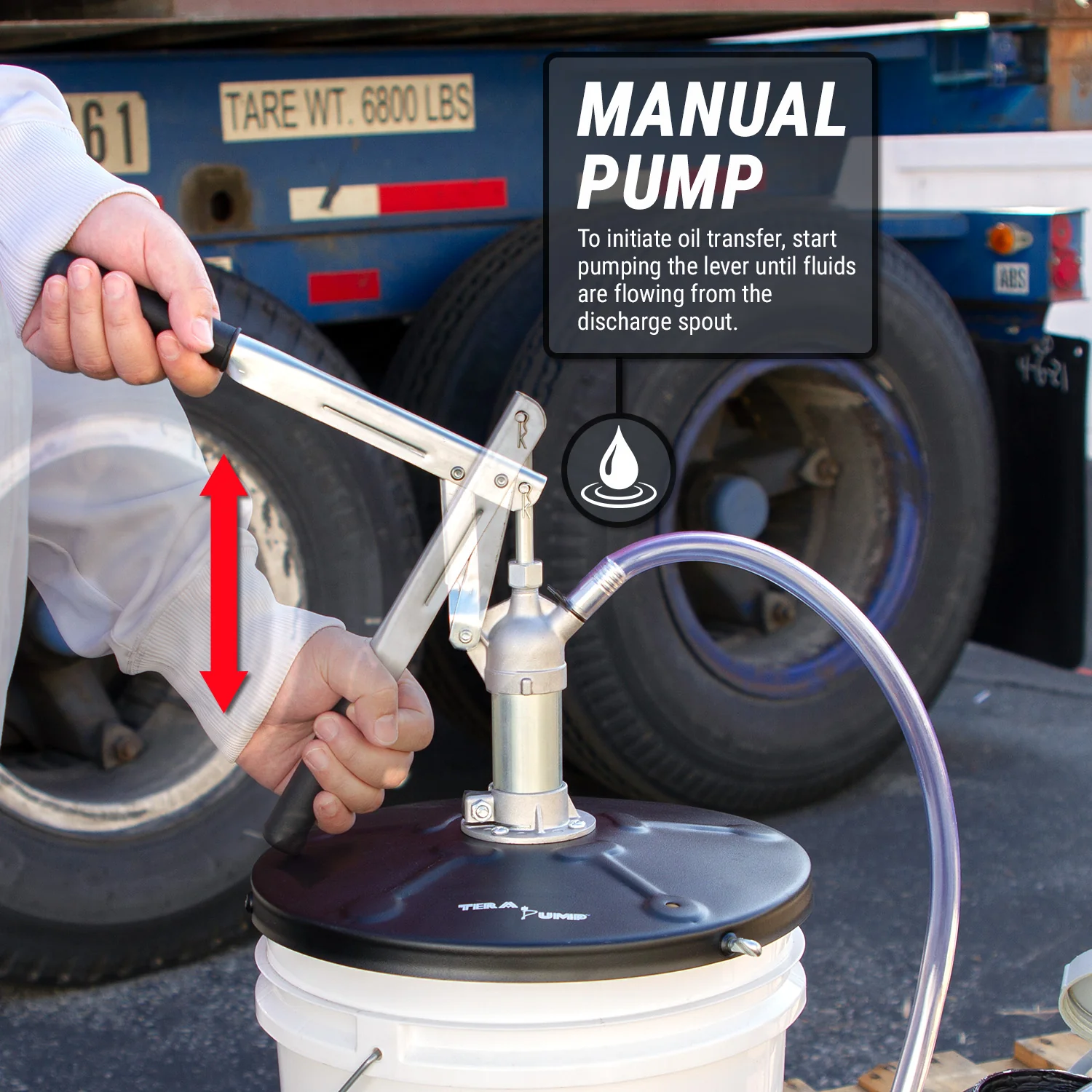

Manual Pumps: These pumps rely on manual operation, typically a lever or handle mechanism, to generate the necessary pressure for pumping oil. They are simple, cost-effective, and suitable for light-duty applications where portability and independence from power sources are essential.

Electric Pumps: Powered by electricity, these pumps offer consistent and efficient oil transfer. They are suitable for high-volume applications and can be used in both industrial and commercial settings. Electric pumps are available in various configurations, including submersible and transfer pump designs.

Air-Operated Pumps: Also known as pneumatic pumps, these units are driven by compressed air, making them ideal for use in hazardous or flammable environments where electric pumps may pose a risk. Air-operated pumps are often used in industrial settings, such as automotive repair shops and manufacturing facilities.

Rotary Pumps: These pumps feature a rotating mechanism that creates suction and facilitates the transfer of oil. Rotary pumps are known for their high flow rates and are commonly used in applications that require continuous or high-volume oil transfer, such as in manufacturing processes or bulk fluid handling.

Diaphragm Pumps: Utilizing a flexible diaphragm to create a pumping action, these pumps are suitable for transferring a wide range of viscous fluids, including oils. Diaphragm pumps are self-priming and can handle particles or debris without damaging the pump, making them versatile for various applications.

Each type of 5 gallon oil pump has its advantages and limitations, and the choice depends on factors such as the intended use, required flow rate, portability, and compatibility with the specific oil or fluid being transferred.

Materials and Construction

A typical 5 gallon oil pump is constructed using a combination of durable materials designed to withstand the rigors of transferring and dispensing various types of oils and lubricants. The pump housing, which encloses the internal mechanisms, is often made from cast iron or aluminum alloy, providing strength and resistance to corrosion.

The internal components, such as the gears, shafts, and bearings, are typically manufactured from high-quality steel or other metal alloys. These materials are chosen for their durability, wear resistance, and ability to operate under high pressures and temperatures.

The pump’s seals and gaskets are typically made from materials like Buna-N rubber, Viton, or other synthetic elastomers, which are resistant to the chemicals found in oils and lubricants. These seals play a crucial role in preventing leaks and ensuring efficient operation.

The pump’s exterior may feature a powder-coated or painted finish to protect against corrosion and provide a professional appearance. Additionally, some models may incorporate plastic or composite materials for non-critical components, reducing weight and cost without compromising performance.

Design factors, such as the pump’s flow rate, pressure capabilities, and compatibility with different types of oils, are carefully considered during the manufacturing process. Manufacturers often employ advanced engineering techniques and computer simulations to optimize the pump’s design for maximum efficiency and reliability.

Overall, the materials and construction of a 5 gallon oil pump are carefully selected and engineered to provide a durable, reliable, and efficient solution for transferring and dispensing oils and lubricants in various industrial, automotive, and commercial settings.

Key Features

A 5 gallon oil pump is designed to efficiently transfer and dispense various types of oils, lubricants, and other viscous fluids. Some of the key features to consider include:

Flow Rates: The flow rate of a 5 gallon oil pump determines how quickly it can transfer fluids. Higher flow rates are ideal for applications that require rapid fluid transfer or dispensing. Flow rates can range from a few gallons per minute (GPM) for light-duty pumps to over 10 GPM for heavy-duty models.

Pressure Ratings: The pressure rating indicates the maximum pressure the pump can withstand without leaking or failing. Higher pressure ratings are necessary for applications that involve long hose runs, elevated discharge points, or highly viscous fluids. Typical pressure ratings range from 50 PSI for low-pressure pumps to over 300 PSI for high-pressure models.

Pump Mechanisms: The pump mechanism determines how the fluid is transferred and the efficiency of the process. Common mechanisms include:

- Rotary Vane Pumps: These pumps use rotating vanes to create a vacuum and draw fluid into the pump chamber, then discharge it through the outlet. They are known for their smooth, low-pulsation flow and self-priming capabilities.

- Gear Pumps: Gear pumps use the meshing of two or more gears to create a vacuum and move fluid through the pump. They are highly efficient and can handle a wide range of viscosities, but may require priming.

- Piston Pumps: Piston pumps use a reciprocating piston to draw fluid into the pump chamber and then force it out through the outlet. They are known for their high pressure capabilities and ability to handle viscous fluids, but can be more prone to pulsation and require more maintenance.

The choice of pump mechanism depends on factors such as fluid viscosity, required flow rate, pressure requirements, and operating conditions.

Applications

5 gallon oil pumps are versatile and widely used in various applications, including automotive, industrial, and machine shops. In the automotive industry, these pumps are essential for transferring and dispensing various automotive fluids, such as engine oil, transmission fluid, and gear oil. They are commonly used in service stations, quick lube centers, and automotive repair shops to efficiently and safely transfer oil from larger containers to smaller ones or directly into vehicles.

In industrial settings, 5 gallon oil pumps are employed for lubricating machinery, filling reservoirs, and transferring oils and lubricants. They are often found in manufacturing plants, factories, and maintenance facilities, where they help ensure smooth operation and proper lubrication of equipment, reducing wear and tear, and extending the lifespan of machinery.

Machine shops and metalworking facilities also rely heavily on 5 gallon oil pumps. These pumps are used to transfer cutting fluids, coolants, and lubricants to various metalworking machines, such as lathes, mills, and drill presses. Proper lubrication and cooling are crucial in these applications to maintain tool life, achieve precise cuts, and prevent overheating and damage to the workpiece and machinery.

Furthermore, 5 gallon oil pumps are commonly used in the maintenance and servicing of hydraulic systems, where they are employed to transfer hydraulic fluids to and from reservoirs, cylinders, and other components. These pumps play a vital role in ensuring the smooth operation of hydraulic equipment, such as forklifts, excavators, and construction machinery.

Installation and Setup

Installing a 5 gallon oil pump requires careful planning and adherence to manufacturer guidelines. Proper mounting is crucial for safe and efficient operation. The pump should be securely fastened to a level, stable surface using mounting brackets or bolts. Vibration isolation pads may be necessary to reduce noise and prevent damage.

Plumbing connections are equally important. The inlet and outlet ports must be connected to the appropriate piping or hose lines using compatible fittings and sealants. Ensure that all connections are tight and leak-free. Improper connections can lead to leaks, reduced flow, and potential safety hazards.

Priming the pump is an essential step before operation. Most 5 gallon oil pumps are self-priming, but they may require manual priming for the initial startup or after maintenance. Follow the manufacturer’s instructions for proper priming procedures, which typically involve filling the pump casing with the fluid being pumped and ensuring that all air is purged from the system.

Operation and Use

To operate a 5 gallon oil pump, first ensure that all connections are secure and the pump is properly installed. Prime the pump by filling the inlet line and pump body with the fluid you’ll be transferring. This will help the pump achieve its full flow rate more quickly.

Starting the Pump

Most 5 gallon oil pumps have an on/off switch or a toggle to start and stop operation. Larger models may have a control panel. Follow the manufacturer’s instructions for startup procedures. Allow the pump to run briefly before opening any valves to build up pressure.

Adjusting Flow Rate

Many oil transfer pumps feature an adjustable flow rate or bypass valve to control the output volume. Start on a lower setting, then increase the flow as needed for your application. Avoid running the pump at too high of a rate, as this can cause overheating or damage.

Safety Precautions

Always take proper safety measures when operating an oil pump. Ensure adequate ventilation, as oil fumes can be hazardous. Wear protective equipment like gloves, goggles, and clothing to avoid exposure. Never run the pump when leaks are present, and do not let the pump run dry for extended periods. Follow all manufacturer warnings and safety guidelines.

Maintenance and Troubleshooting

Proper maintenance is crucial for ensuring the longevity and efficient operation of a 5-gallon oil pump. Regular cleaning and part replacement can help prevent breakdowns and extend the lifespan of the pump.

Cleaning

Keeping the pump clean is essential to prevent clogs and ensure smooth operation. Follow these steps for effective cleaning:

- Disassemble the Pump: Carefully disassemble the pump according to the manufacturer’s instructions, ensuring all components are properly separated for thorough cleaning.

- Remove Debris: Use a soft-bristle brush or compressed air to remove any accumulated debris, dirt, or residue from the pump’s interior components and exterior surfaces.

- Clean with Appropriate Solvents: Use recommended solvents or cleaning solutions to dissolve and remove any stubborn oil or grease buildup. Avoid harsh chemicals that could damage the pump’s components.

- Rinse and Dry: Thoroughly rinse all components with clean water or the recommended solvent to remove any remaining residue. Allow the components to dry completely before reassembling the pump.

Part Replacement

Over time, certain parts of the pump may wear out or become damaged, requiring replacement. Common parts that may need replacement include:

- Seals and Gaskets: These components are susceptible to wear and tear, and their failure can lead to leaks or reduced efficiency. Replace them periodically or as recommended by the manufacturer.

- Valves: Faulty valves can cause leaks, reduced flow, or improper pressure. Replace worn or damaged valves to ensure proper operation.

- Impellers: The impeller is a crucial component responsible for moving the oil. If it becomes worn or damaged, it can significantly impact the pump’s performance and should be replaced.

- Motor: In some cases, the motor may need to be replaced if it fails or becomes excessively noisy or inefficient.

Common Issues and Troubleshooting

Even with proper maintenance, issues may arise with a 5-gallon oil pump. Here are some common problems and troubleshooting steps:

- Reduced Flow or Pressure: If the pump is not delivering the expected flow or pressure, check for clogs, worn impellers, or faulty valves. Clean or replace the affected components as necessary.

- Leaks: If you notice leaks from the pump, inspect the seals, gaskets, and connections. Replace any worn or damaged components, and ensure proper reassembly.

- Excessive Noise or Vibration: Unusual noises or vibrations can indicate worn bearings, misalignment, or other mechanical issues. Inspect and replace any faulty components as needed.

- Motor Overheating: If the motor overheats, check for proper ventilation, lubrication, and any obstructions that may be causing excessive strain on the motor.

Regular maintenance, timely part replacement, and proper troubleshooting can help ensure the reliable and efficient operation of your 5-gallon oil pump, minimizing downtime and maximizing its lifespan.

Accessories and Attachments

5 gallon oil pumps often come with various accessories and attachments to enhance their functionality and versatility. These additional components can streamline the oil transfer process, improve efficiency, and provide greater control over the flow rate and direction.

Hose Kits

One of the most common accessories for 5 gallon oil pumps is a hose kit. These kits typically include a length of flexible hose, often made from durable materials like nitrile or PVC, along with necessary fittings and connectors. Hose kits allow for easy connection between the pump and the oil container or receptacle, enabling convenient and mess-free oil transfer. They come in various lengths to accommodate different setups and can be replaced as needed.

Nozzles

Nozzles are attachments that fit onto the end of the hose or pump outlet, providing precise control over the oil flow. Different nozzle types are available, including rigid and flexible options, as well as those with automatic shut-off mechanisms. Rigid nozzles offer a more directed stream, while flexible nozzles can bend and maneuver into tight spaces. Automatic shut-off nozzles help prevent spills and overfilling by stopping the flow when the desired level is reached.

Flow Meters

For applications that require accurate monitoring of the oil transfer volume, flow meters can be invaluable accessories. These devices measure and display the flow rate and total volume of oil pumped, allowing for precise tracking and record-keeping. Flow meters can be integrated into the pump system or installed as separate inline units, depending on the specific setup.

Filters

In some cases, it may be necessary to filter the oil during the transfer process to remove contaminants or particulates. Oil filters can be attached to the pump’s inlet or outlet, ensuring that the transferred oil is clean and free of debris. These filters come in various sizes and micron ratings to accommodate different levels of filtration requirements.

Mounting Brackets and Stands

Mounting brackets and stands are accessories that facilitate the secure and stable positioning of the 5 gallon oil pump. Brackets allow for easy mounting on walls or other surfaces, while stands provide a sturdy base for freestanding operation. These accessories help prevent accidental spills or tipping, ensuring safe and controlled oil transfer.

By utilizing the appropriate accessories and attachments, 5 gallon oil pumps can be tailored to meet specific application needs, enhancing their functionality, efficiency, and ease of use.

Factors to Consider When Buying

When shopping for a 5-gallon oil pump, there are several key factors to consider to ensure you select the right model for your specific needs:

Brand and Quality: Choose a reputable brand known for manufacturing high-quality, durable pumps. Well-established brands often offer better warranties, customer support, and reliable performance.

Cost and Budget: 5-gallon oil pumps can vary significantly in price, ranging from budget-friendly options to premium, heavy-duty models. Determine your budget and strike a balance between cost and features that meet your requirements.

Flow Rate: Consider the flow rate you need for your application. A higher flow rate will allow you to transfer oil more quickly, but may also increase the pump’s size, weight, and cost.

Pump Material: The material of the pump’s construction is crucial for durability and compatibility with the fluids being transferred. Common materials include cast iron, aluminum, and various plastics, each with its own advantages and limitations.

Power Source: Oil pumps can be powered by electricity, compressed air, or manual operation. Electric pumps offer convenience but require a power source, while air-powered and manual pumps provide portability but may be more labor-intensive.

Portability and Size: If you need to move the pump frequently or have limited space, consider a compact and lightweight design. Larger, heavier pumps may be more suitable for stationary applications.

Hose and Accessories: Evaluate the included hoses, nozzles, and other accessories to ensure compatibility with your containers and desired functionality.

Safety Features: Look for safety features like automatic shut-off, overheat protection, and anti-spark design to prevent accidents and protect your equipment.

Intended Use: Consider the specific application for which you need the pump, such as transferring lubricants, fuel oils, or other fluids. Some pumps may be better suited for certain fluids than others.

By carefully evaluating these factors, you can select a 5-gallon oil pump that meets your performance requirements, budget, and operational needs, ensuring efficient and reliable fluid transfer for your application.

Top Brands and Models

The market for 5 gallon oil pumps is dominated by a few leading manufacturers known for their quality, reliability, and innovative designs. These brands have established themselves as industry leaders through their commitment to excellence and their ability to meet the diverse needs of various applications.

One of the most prominent names in the industry is Graco. Their line of 5 gallon oil pumps is renowned for its durability and performance. Graco’s pumps are designed with high-quality materials and advanced features, making them suitable for demanding industrial and commercial applications. Their flagship models, such as the Graco XTR7 and the Graco GH230, are widely used in automotive, manufacturing, and construction sectors.

Another major player in the market is Lincoln Industrial. Their 5 gallon oil pumps are known for their precision engineering and user-friendly designs. Lincoln’s pumps are often favored by professionals in the automotive and heavy equipment industries due to their reliable performance and ease of maintenance. Popular models from Lincoln include the Lincoln 1162 and the Lincoln 1844.

Alemite, a subsidiary of the renowned Parker Hannifin Corporation, is also a prominent manufacturer of 5 gallon oil pumps. Alemite’s pumps are designed with a focus on efficiency and versatility, making them suitable for a wide range of applications. Their models, such as the Alemite 8701 and the Alemite 8702, are widely used in industries like agriculture, mining, and construction.

Balcrank, another well-established brand, offers a diverse range of 5 gallon oil pumps known for their rugged construction and user-friendly features. Balcrank’s pumps are often chosen for their ability to withstand harsh environments and deliver consistent performance. Popular models from Balcrank include the Balcrank 1800 and the Balcrank 2000 series.

In addition to these major brands, there are several other manufacturers offering high-quality 5 gallon oil pumps, such as Lubriplate, Samoa, and Raasm. These companies continue to innovate and introduce new models with advanced features to meet the evolving needs of various industries.

Industry Standards and Regulations

When it comes to 5 gallon oil pumps, there are several industry standards and regulations that manufacturers and users must adhere to. These guidelines ensure the safe and efficient operation of these pumps, as well as minimize their environmental impact.

One of the primary standards is the National Fire Protection Association (NFPA) code 30, which outlines the requirements for the safe storage, handling, and use of flammable and combustible liquids, including oils. This code covers aspects such as tank design, ventilation, spill control, and fire prevention measures.

Additionally, the Occupational Safety and Health Administration (OSHA) has regulations in place for the safe handling and use of oil pumps in industrial settings. These regulations cover topics such as employee training, personal protective equipment (PPE), and hazard communication.

Many 5 gallon oil pumps are also required to meet certifications from organizations like Underwriters Laboratories (UL) or the Canadian Standards Association (CSA). These certifications ensure that the pumps have been tested and meet strict safety standards for electrical components, fire resistance, and overall design.

In terms of environmental regulations, the Environmental Protection Agency (EPA) has guidelines in place for the proper disposal of used oil and the prevention of spills or leaks. Manufacturers and users must comply with these regulations to minimize the environmental impact of their operations.

It’s important to note that industry standards and regulations may vary depending on the specific application and location of the 5 gallon oil pump. Manufacturers and users should always consult the latest codes and regulations to ensure compliance and maintain a safe working environment.

Environmental Impact

Emissions

5 gallon oil pumps are typically powered by electricity or compressed air, which can contribute to greenhouse gas emissions depending on the energy source. Electric pumps draw power from the grid, which may involve fossil fuel-based electricity generation. Compressed air pumps require compressors that consume energy, potentially from non-renewable sources. However, both options generally have lower direct emissions compared to gasoline or diesel-powered pumps.

Energy Use

The energy efficiency of 5 gallon oil pumps can vary significantly based on the pump design, motor type, and operating conditions. Inefficient pumps or improper sizing for the application can lead to higher energy consumption and associated emissions from electricity generation. Choosing energy-efficient models and properly sizing the pump can help minimize energy use and environmental impact.

Recyclability

Many 5 gallon oil pumps are constructed from metals like steel, aluminum, or cast iron, which are generally recyclable materials. However, some models may incorporate plastic components or coatings that can complicate recycling efforts. Proper disposal and recycling of pumps at the end of their service life can help reduce waste and conserve resources.

Emerging Trends and Innovations

The world of 5-gallon oil pumps is continuously evolving, driven by the need for increased efficiency, cost-effectiveness, and environmental sustainability. One of the most significant emerging trends is the integration of advanced electronic controls and monitoring systems. These systems allow for precise control over flow rates, pressure, and other operational parameters, ensuring optimal performance and reducing waste.

Another notable trend is the development of energy-efficient designs. Manufacturers are exploring ways to reduce energy consumption through improved motor technologies, optimized pump geometries, and the incorporation of variable-speed drives. These advancements not only lower operational costs but also contribute to a reduced carbon footprint.

The use of advanced materials, such as lightweight composites and corrosion-resistant alloys, is also gaining traction. These materials enhance durability, extend service life, and enable the pumps to operate in harsh environments, expanding their application potential.

Furthermore, the integration of Internet of Things (IoT) technology is revolutionizing the way 5-gallon oil pumps are monitored and maintained. Remote monitoring capabilities allow for real-time data collection, predictive maintenance, and seamless integration with enterprise resource planning (ERP) systems, enabling more efficient resource allocation and proactive maintenance schedules.

Lastly, the pursuit of renewable energy sources is driving the development of pumps designed specifically for biofuels and other alternative fuels. As the demand for sustainable energy solutions grows, these pumps will play a crucial role in facilitating the transition to a more environmentally friendly future.

Resources and Further Reading

For those seeking more in-depth information on 5 gallon oil pumps, several resources are available:

Books

- “Industrial Fluid Power” by Brendan J. Casey – This comprehensive book covers various types of pumps, including oil pumps, and their applications in industrial settings.

- “Pump Handbook” by Igor J. Karassik et al. – A classic reference book that provides detailed information on pump design, selection, and operation, including sections on oil pumps.

Websites

- PumpScout.com – An online resource dedicated to pump education, with articles, guides, and forums specifically related to oil pumps.

- PumpingMachinery.com – A website offering resources, news, and product information on various types of pumps, including oil pumps.

Expert Interviews

- “Insights from an Oil Pump Manufacturer” – An interview with a leading oil pump manufacturer, discussing the latest trends, challenges, and best practices in the industry.

- “Oil Pump Maintenance: Tips from a Seasoned Technician” – An interview with an experienced technician, sharing valuable insights on proper maintenance and troubleshooting of oil pumps.

These resources can provide valuable information, technical details, and expert perspectives to help readers deepen their understanding of 5 gallon oil pumps and make informed decisions.