An O2 sensor socket, also known as an oxygen sensor socket, is a specialized tool used to remove and install the oxygen sensors in a vehicle’s exhaust system. The oxygen sensor, commonly referred to as the O2 sensor, is a crucial component that monitors the air-fuel mixture in the exhaust gases, providing vital information to the engine’s computer system for optimal fuel efficiency and emissions control.

The O2 sensor socket is designed to fit snugly over the sensor, allowing mechanics to securely grip and twist it during removal or installation. These sockets are typically made of durable materials like chrome-vanadium steel or impact-resistant plastics to withstand the high temperatures and harsh conditions found in the exhaust system.

Oxygen sensors are typically located in the exhaust pipe, either before or after the catalytic converter, depending on the vehicle’s design. Some vehicles may have multiple O2 sensors, with one sensor monitoring the air-fuel mixture before the catalytic converter and another monitoring the efficiency of the converter itself.

Table of Contents

Purpose and Function

The O2 sensor socket plays a crucial role in the vehicle’s emission control system by facilitating the proper functioning of the oxygen sensor, also known as the lambda sensor. This sensor is responsible for monitoring the air/fuel mixture in the exhaust gases, providing vital feedback to the engine control unit (ECU) for optimal combustion and emission regulation.

The primary purpose of the O2 sensor socket is to securely hold the oxygen sensor in place while allowing electrical connections to be made between the sensor and the vehicle’s wiring harness. This connection enables the sensor to communicate its readings to the ECU, which then adjusts the air/fuel ratio accordingly to maintain efficient combustion and minimize harmful emissions.

Proper air/fuel mixture is essential for complete combustion and reduced emissions. An overly rich mixture (too much fuel) can lead to increased carbon monoxide and hydrocarbon emissions, while an excessively lean mixture (too much air) can result in elevated nitrogen oxide emissions and potentially damage the catalytic converter. By continuously monitoring the exhaust gases, the oxygen sensor provides real-time data to the ECU, allowing it to make precise adjustments to the fuel injection system and maintain the ideal air/fuel ratio.

Types of O2 Sensor Sockets

O2 sensor sockets come in various types, each designed to meet specific requirements and applications. The primary types include:

Wired O2 Sensor Sockets

Wired O2 sensor sockets are the most common type and feature a physical wire connection to the vehicle’s electrical system. They are reliable and durable, making them suitable for most automotive applications. Wired sockets are available in different wire lengths and connector types to accommodate various vehicle models.

Wireless O2 Sensor Sockets

Wireless O2 sensor sockets use radio frequency (RF) or Bluetooth technology to transmit data wirelessly to the vehicle’s computer system. These sockets are convenient for hard-to-reach areas and can simplify installation. However, they may be more susceptible to interference and require a power source, such as a battery.

Heated O2 Sensor Sockets

Heated O2 sensor sockets are designed for vehicles that operate in cold climates or experience frequent cold starts. The built-in heating element helps to warm up the sensor more quickly, improving its accuracy and response time. Heated sockets are particularly useful for vehicles that experience frequent short trips or idling periods.

Unheated O2 Sensor Sockets

Unheated O2 sensor sockets are the most basic type and do not include a heating element. They are suitable for most standard driving conditions and are generally more affordable than heated sockets. However, they may take longer to reach optimal operating temperature, which can affect their performance in colder environments.

Each type of O2 sensor socket has its advantages and is designed for specific applications. Factors such as driving conditions, vehicle make and model, and personal preferences should be considered when selecting the appropriate socket type.

Installation and Removal

The installation and removal of an O2 sensor socket require careful attention to ensure proper functioning and avoid potential damage. Here are the steps to follow:

Installation:

- Preparation: Ensure the engine is cool and locate the O2 sensor socket. Clean the area around the socket to remove any dirt or debris.

- Tools Required: You’ll need an O2 sensor socket wrench, which is specifically designed to fit the hexagonal shape of the sensor socket. Additionally, have a ratchet and extension ready.

- Safety Precautions: Wear protective gloves and eye protection, as the sensor and socket can be hot, and debris may be present.

- Installation Process: Apply a small amount of anti-seize compound to the threads of the new O2 sensor socket. Carefully thread the socket into the exhaust manifold or downpipe, tightening it with the O2 sensor socket wrench. Avoid over-tightening, as this can damage the threads.

- Torque Specifications: Consult the manufacturer’s specifications for the recommended torque settings and tighten the socket accordingly using a torque wrench.

Removal:

- Preparation: Follow the same preparation steps as for installation, ensuring the engine is cool and the area around the sensor socket is clean.

- Tools Required: You’ll need the same O2 sensor socket wrench, ratchet, and extension as for installation.

- Safety Precautions: Wear protective gloves and eye protection, as the sensor and socket may be hot, and debris may be present.

- Removal Process: Fit the O2 sensor socket wrench onto the sensor socket and turn it counterclockwise to loosen it. If the socket is stuck or seized, you may need to apply penetrating oil or heat to help break it free. Avoid excessive force, as this can damage the threads or surrounding components.

- Inspection: Once the sensor socket is removed, inspect it for any signs of damage or excessive wear. If necessary, replace it with a new one.

Remember, proper installation and removal techniques are crucial to ensure the longevity and accurate functioning of the O2 sensor system, which plays a vital role in monitoring and controlling the vehicle’s emissions.

Maintenance and Troubleshooting

Like any automotive component, O2 sensor sockets can experience issues over time, leading to potential problems with your vehicle’s emissions and fuel efficiency. Regular maintenance and troubleshooting can help identify and address these issues before they escalate.

Common Issues with O2 Sensor Sockets

- Corrosion and Rust: O2 sensor sockets are exposed to high temperatures and exhaust gases, which can cause corrosion and rust over time. This can lead to a poor electrical connection or even complete failure of the sensor.

- Stripped or Damaged Threads: Improper installation or removal of the O2 sensor can strip or damage the threads in the sensor socket. This can make it difficult or impossible to properly secure the sensor, leading to potential leaks and sensor failure.

- Debris and Contaminants: Over time, debris and contaminants from the exhaust system can accumulate in the sensor socket, interfering with the sensor’s ability to accurately measure oxygen levels.

Signs of O2 Sensor Socket Failure

- Check Engine Light: A malfunctioning O2 sensor socket can trigger the Check Engine Light, indicating an issue with the emissions system.

- Poor Fuel Economy: A faulty O2 sensor socket can cause the engine to run too rich or too lean, resulting in decreased fuel efficiency.

- Rough Idle or Stalling: Improper oxygen sensor readings can disrupt the air-fuel mixture, leading to a rough idle or engine stalling.

- Failed Emissions Test: A faulty O2 sensor socket can cause the vehicle to fail an emissions test due to elevated pollutant levels.

Maintenance Tips

- Regular Inspection: Visually inspect the O2 sensor socket during routine maintenance for signs of corrosion, damage, or debris buildup.

- Proper Installation and Removal: Follow the manufacturer’s instructions carefully when installing or removing the O2 sensor, using the appropriate tools and techniques to avoid damaging the socket.

- Cleaning: If debris or contaminants are present, carefully clean the sensor socket using a wire brush or compressed air.

- Lubrication: Apply a small amount of anti-seize compound to the threads of the sensor and socket to prevent future seizing or galling.

Troubleshooting Techniques

- Visual Inspection: Perform a thorough visual inspection of the O2 sensor socket, looking for signs of corrosion, damage, or debris buildup.

- Resistance Testing: Use a multimeter to check the resistance of the O2 sensor socket wiring and connections. Refer to the manufacturer’s specifications for the correct resistance values.

- Continuity Testing: Perform a continuity test on the O2 sensor socket wiring to ensure there are no breaks or open circuits.

- Voltage Testing: With the engine running, use a multimeter to check the voltage output of the O2 sensor. Refer to the manufacturer’s specifications for the expected voltage range.

- Replacement: If the O2 sensor socket is damaged or cannot be repaired, replace it with a high-quality aftermarket or OEM replacement part.

By following these maintenance and troubleshooting techniques, you can help ensure the proper functioning of your vehicle’s O2 sensor sockets, contributing to better emissions control, fuel efficiency, and overall engine performance.

Importance of Quality O2 Sensor Sockets

The O2 sensor socket plays a crucial role in ensuring proper oxygen sensor function, which directly impacts vehicle performance and emissions. Using a high-quality O2 sensor socket offers several benefits:

- Improved Sensor Accuracy: Premium sockets are designed with tighter tolerances and better materials, ensuring a secure and precise fit for the oxygen sensor. This enhances the sensor’s ability to accurately measure the air-fuel ratio, leading to optimized engine combustion and reduced emissions.

- Longer Sensor Life: Inferior sockets can cause premature wear or damage to the oxygen sensor due to improper fit, vibrations, or exposure to contaminants. High-quality sockets protect the sensor from these issues, extending its lifespan and reducing replacement costs.

- Better Engine Performance: Accurate oxygen sensor readings enable the engine control unit (ECU) to make precise adjustments to the air-fuel mixture, resulting in improved fuel efficiency, increased power output, and smoother engine operation.

- Reduced Emissions: Properly functioning oxygen sensors are essential for maintaining low emission levels. Quality sockets ensure accurate sensor readings, allowing the ECU to make the necessary adjustments to minimize harmful exhaust emissions, such as carbon monoxide, hydrocarbons, and nitrogen oxides.

- Easier Installation and Removal: Premium O2 sensor sockets are designed with ergonomic handles and robust construction, making installation and removal easier and reducing the risk of cross-threading or damaging the sensor or engine components.

- Durability and Longevity: High-quality sockets are built to withstand extreme temperatures, vibrations, and other harsh conditions encountered in the engine bay, ensuring long-lasting performance and reliability.

Investing in quality O2 sensor sockets may cost slightly more upfront, but the benefits in terms of improved vehicle performance, reduced emissions, and extended component life often outweigh the initial expense. By prioritizing high-quality sockets, vehicle owners can contribute to a cleaner environment while enjoying optimal engine operation and fuel efficiency.

Choosing the Right O2 Sensor Socket

Selecting the appropriate O2 sensor socket is crucial for ensuring proper installation, longevity, and optimal performance of your vehicle’s oxygen sensor. Several factors should be considered when choosing an O2 sensor socket to ensure compatibility and durability.

Vehicle Make and Model: The first and most important factor is to identify the specific make, model, year, and engine type of your vehicle. O2 sensor sockets are designed to fit specific applications, and using the wrong socket can lead to improper installation, damage to the sensor or socket, and potential engine issues.

Compatibility: Once you have identified your vehicle’s specifications, it is essential to choose an O2 sensor socket that is explicitly designed and listed as compatible with your make and model. Reputable manufacturers provide detailed compatibility information, ensuring a perfect fit and seamless installation.

Material and Construction: O2 sensor sockets are typically made from high-quality materials such as heat-treated chrome vanadium steel or other durable alloys. These materials are chosen for their strength, resistance to wear and tear, and ability to withstand the harsh environment of the exhaust system.

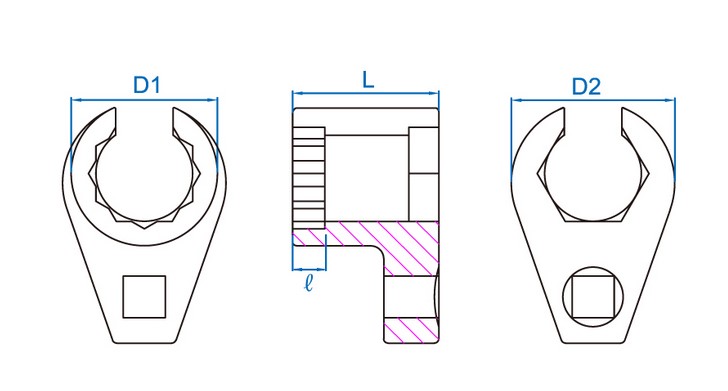

Socket Design: O2 sensor sockets come in various designs, including swivel heads, knurled grips, and different socket depths. The design should be chosen based on the specific location and accessibility of the oxygen sensor on your vehicle, ensuring ease of use and proper engagement with the sensor.

Brand Reputation and Warranty: When selecting an O2 sensor socket, it is advisable to choose products from reputable brands known for their quality and durability. Established manufacturers often offer warranties, ensuring customer satisfaction and providing a level of assurance for your purchase.

By considering these factors, you can ensure that you select the right O2 sensor socket for your vehicle, enabling proper installation, prolonged sensor life, and optimal engine performance.

Emission Testing and O2 Sensor Sockets

The proper functioning of the oxygen (O2) sensor sockets plays a crucial role in ensuring accurate emission testing results. Emission tests are designed to measure the levels of various pollutants, such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx), present in a vehicle’s exhaust gases. The O2 sensor sockets are responsible for providing a secure and reliable connection between the O2 sensors and the vehicle’s electronic control module (ECM).

If an O2 sensor socket is faulty or corroded, it can lead to inaccurate readings from the O2 sensors. This, in turn, can cause the ECM to miscalculate the air-fuel ratio, resulting in incomplete combustion and higher emission levels. Proper functioning of the O2 sensor sockets ensures that the ECM receives accurate data from the O2 sensors, enabling it to make the necessary adjustments to maintain optimal air-fuel ratios and minimize emissions.

During emission testing, technicians may need to inspect the O2 sensor sockets for any signs of wear, corrosion, or damage. Loose or corroded sockets can introduce electrical resistance, causing intermittent or inaccurate signals from the O2 sensors. This can lead to false emission test results, potentially allowing vehicles with higher-than-acceptable emission levels to pass the test or causing vehicles with acceptable emission levels to fail unnecessarily.

To ensure accurate emission testing, it is essential to replace any faulty or damaged O2 sensor sockets. Regular maintenance and inspection of these components can help identify potential issues before they lead to inaccurate emission test results. Additionally, using high-quality O2 sensor sockets designed specifically for the vehicle’s make and model can further enhance the reliability and accuracy of the emission testing process.

OEM vs. Aftermarket O2 Sensor Sockets

When it comes to replacing an O2 sensor socket, you have the option of choosing between an Original Equipment Manufacturer (OEM) part or an aftermarket alternative. Each option has its own set of advantages and disadvantages, and the choice ultimately depends on your specific needs and budget.

OEM O2 Sensor Sockets

OEM O2 sensor sockets are designed and manufactured by the same company that produced the original component for your vehicle. These sockets are engineered to meet the exact specifications and quality standards set by the automaker. Some key advantages of OEM O2 sensor sockets include:

- Guaranteed fit and compatibility with your vehicle

- Adherence to strict quality control measures

- Longer lifespan and durability

- Improved emissions and fuel efficiency performance

However, OEM parts tend to be more expensive than their aftermarket counterparts, which can be a significant consideration for budget-conscious consumers.

Aftermarket O2 Sensor Sockets

Aftermarket O2 sensor sockets are produced by third-party manufacturers and are designed to be compatible with various vehicle makes and models. While they may not be an exact match for your vehicle’s original equipment, many aftermarket suppliers strive to meet or exceed OEM quality standards. Some advantages of aftermarket O2 sensor sockets include:

- Lower cost compared to OEM parts

- Wider availability and easier accessibility

- Competitive quality from reputable brands

- Suitable for budget-conscious consumers

On the other hand, aftermarket O2 sensor sockets may not always match the precise fitment or performance of OEM parts, and quality can vary significantly between brands and manufacturers.

Cost Considerations

One of the primary factors influencing the choice between OEM and aftermarket O2 sensor sockets is cost. OEM parts typically carry a premium price tag due to the brand name, quality assurance, and strict manufacturing standards. Aftermarket alternatives, while generally more affordable, can vary in quality and pricing depending on the manufacturer’s reputation and product specifications.

It’s essential to weigh the upfront cost against the potential long-term benefits and lifespan of the O2 sensor socket. In some cases, investing in an OEM part may be more cost-effective in the long run, while in other situations, an aftermarket option may provide a suitable balance between cost and performance.

Ultimately, the decision between OEM and aftermarket O2 sensor sockets should be based on your specific needs, budget, and the level of quality and performance you require for your vehicle.

Future of O2 Sensor Sockets

As automotive technology continues to evolve, the future of O2 sensor sockets is promising. Manufacturers are exploring new materials and designs to improve durability, longevity, and performance. One emerging trend is the use of advanced ceramics and high-temperature alloys that can withstand extreme conditions better than traditional materials.

Another area of innovation is the integration of sensor sockets with advanced diagnostic capabilities. These smart sockets could potentially monitor the health of the sensor and provide real-time data to the vehicle’s onboard computer, enabling predictive maintenance and reducing the risk of sensor failure.

Additionally, researchers are investigating the potential of wireless O2 sensor sockets, which could eliminate the need for physical connections and simplify installation and maintenance processes. This technology could also enable remote monitoring and diagnostics, further enhancing the efficiency of emission control systems.

As the automotive industry continues to prioritize emissions reduction and fuel efficiency, the demand for accurate and reliable O2 sensor sockets will likely increase. Manufacturers may focus on developing sockets with improved accuracy and responsiveness, ensuring precise air-fuel ratio adjustments for optimal engine performance and reduced emissions.

Moreover, the advent of electric and hybrid vehicles presents new challenges and opportunities for O2 sensor socket design. While these vehicles may have different emission control requirements, the need for robust and reliable sensor sockets remains crucial for monitoring and optimizing the performance of their powertrain systems.

Overall, the future of O2 sensor sockets is shaped by the pursuit of innovation, efficiency, and environmental sustainability in the automotive industry. As new technologies emerge and regulations evolve, manufacturers will continue to refine and enhance these critical components, ensuring reliable and accurate emission control systems for years to come.

FAQs and Common Misconceptions

Q: What is the purpose of an O2 sensor socket?

A: An O2 sensor socket is a specialized tool used to safely remove and install oxygen sensors on a vehicle’s exhaust system. It is designed to grip the sensor securely without damaging it, allowing for proper maintenance and replacement.

Q: Can I use a regular socket or wrench to remove an O2 sensor?

A: It is not recommended to use regular sockets or wrenches to remove O2 sensors. These tools can easily damage the sensor’s delicate wiring or the sensor itself, leading to costly repairs or replacements. O2 sensor sockets are specifically designed for this task and provide a secure grip without causing damage.

Q: Do I need a different O2 sensor socket for each type of sensor?

A: Yes, O2 sensor sockets come in various sizes and designs to accommodate different types of oxygen sensors. Using the wrong socket can result in improper fit, potentially damaging the sensor or the exhaust system components.

Q: Is it necessary to replace O2 sensor sockets regularly?

A: No, O2 sensor sockets are durable tools and do not need frequent replacement unless they become damaged or worn out. Proper care and storage will ensure a long service life for these specialized tools.

Common Misconception: O2 sensor sockets are unnecessary and expensive.

This is a common misconception. While O2 sensor sockets may seem like an additional expense, they are essential for safely and properly removing and installing oxygen sensors. Attempting to use regular tools can lead to costly repairs or replacements, ultimately making O2 sensor sockets a worthwhile investment for anyone performing this type of maintenance.